These applications will - due to browser restrictions - send data between your browser and our server. Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers. The differences in their tensile strengths could be better. Oil at 150 C (300 F); tempered at 150 C (300 F); for 1 h. Sliding spur gear, 67 mm outside diameter. 4. WebAISI 4130 steel can be annealed at 843C (1550F) followed by air cooling at 482C (900F). Accept For each property being compared, the top bar is SAE-AISI 1010 steel and the bottom bar is SAE-AISI 1018 steel. MI UNS Number G10180Ok let's start with SAE 1018 Chemical This type of steel also has excellent cold forming capabilities since it can be easily bent or shaped without cracking or fracturing. WebTensile strength is further divided into three parts, namely: Yield Strength: this is the strength a metal can withstand without permanent deformation. AISI 1018 steel has a range of mechanical properties, including: Tensile strength: AISI 1018 steel has a tensile strength of 64 Ksi (440 MPa). Yield strength: The yield strength of AISI 1018 steel ranges from 290 to 390 MPa. Elastic modulus: The elastic modulus of AISI 1018 steel is around 54 Ksi (370 MPa). All values are % weight. Yield strength: The yield strength of AISI 1018 steel ranges from 290 to 390 MPa. For quenching, heat the material at a temperature of 900-920 C (1650-1700 F) followed by water quenching. SAE-AISI 1018 steel is a carbon (non-alloy) steel formulated for primary forming into wrought products. 1018 is the designation in both the SAE and AISI systems for this material. G10180 is the UNS number. It can also be said to be the maximum strength a component can withstand before plastic deformation. Both SAE-AISI 1018 steel and SAE-AISI 1045 steel are iron alloys. Steels - Endurance Limits and Fatigue Stress, Yield strength is defined in engineering as the amount of stress (Yield point) that a material can undergo before moving from elastic deformation into. What is a Prequalified Welding Procedure Specification, Effects of Welding Variables on Welding Quality, What Materials are Used in Catalytic Converters. 4. It has a Brinell hardness of approximately 125-200, depending on the specific heat treatment and manufacturing conditions.This is relatively low compared to other steels and is not ideal for applications that require high hardness or wear resistance. The carbon content of 1018 is 0.18%, and the carbon content of 1045 steel is 0.45%. Therefore 1018 is used mostly for applications that may involve welding or require a larger quantity where tensile strength and yield strength is not of the highest importance. %%EOF The specific heat treatment method used can affect the mechanical properties and microstructure of the material. Furthermore, hot working processes are also possible with AISI 1018 steel due to its high hot workability. Material is suitable for parts which require cold forming (such as crimping, swaging, or bending). The measured tensile ultimate strength was found to be 1020 MPa. There are 32 material properties with values for both materials. SAE-AISI 1010 (S10C, G10100) Carbon Steel, Electrical Conductivity: Equal Volume, % IACS, Electrical Conductivity: Equal Weight (Specific), % IACS, Resilience: Ultimate (Unit Rupture Work), MJ/m, Resilience: Unit (Modulus of Resilience), kJ/m. These elements make it highly resistant to fatigue and wear in a variety of environments. How does SAE-AISI 1018 steel compare to other iron alloys? Allowable creep strain can be specified - typical 0.1 %/year for steel bolts and piping. The carbon content is what really separates the chemical composition of 1018 and 1045, with 1045 steel having a higher carbon composition. WebProblem Set 3 ME-321 Mechanical and Mechatronics Engineering Department University of Waterloo Problem 1: A 10-mm steel drill rod was heat-treated and ground. It also contains traces of phosphorous and sulfur but fewer impurities than A36. Hardening of AISI 4130 steel can be done with cold working or heat treatment. Your email address will not be published. Both AISI 316 stainless steel and SAE-AISI 1018 steel are iron alloys. As you may have noticed, the carbon content is what identifies the steel grade. 1018 steel is a low-carbon steel that has good weldability and machinability. tO7$;MfP? }SNnr0k6'ax[M+}#$XtbqO|tOhi2DIJ Includes material certificates and CAD models. _2(8N[n _slVG7iLNH*DQ(cQ&V)JAAmRjH0C%-#U'0R

The time dependent deformation due to heavy load over time is known as creep. TIG and MIG welding of 1018 steel can be carried out using ER70S-2 & ER70S-6 filler wire rods. ), the recommended preheat and interpass temperature is above -12 C. endstream

endobj

269 0 obj

<>stream

Bridge St Suite There are exceptions to this relationship. We use cookies to ensure that we give you the best experience on our website to personalize content and adverts and to analyze our traffic using Google Analytics. A carbon steel like 1330 for example has a much higher concentration of manganese. vTF;8GfMV;oWr/*)dB*+C{sU}4mk5k5%i

QWcJ2Ef+DG}!N\G|y-3$9#&BtS*mO"z` a?

Typical 1018 steel applications If you belong to an institution that sets its own citation guidelines, use those instead. 2022, SAE 1018 Properties (Chem., Mech. If you need a steel with high hardness, you may want to consider using a tool steel or a high-carbon steel. WebExpert Answer.

The time dependent deformation due to heavy load over time is known as creep. TIG and MIG welding of 1018 steel can be carried out using ER70S-2 & ER70S-6 filler wire rods. ), the recommended preheat and interpass temperature is above -12 C. endstream

endobj

269 0 obj

<>stream

Bridge St Suite There are exceptions to this relationship. We use cookies to ensure that we give you the best experience on our website to personalize content and adverts and to analyze our traffic using Google Analytics. A carbon steel like 1330 for example has a much higher concentration of manganese. vTF;8GfMV;oWr/*)dB*+C{sU}4mk5k5%i

QWcJ2Ef+DG}!N\G|y-3$9#&BtS*mO"z` a?

Typical 1018 steel applications If you belong to an institution that sets its own citation guidelines, use those instead. 2022, SAE 1018 Properties (Chem., Mech. If you need a steel with high hardness, you may want to consider using a tool steel or a high-carbon steel. WebExpert Answer. Read More, ASTM SAE AISI 1018 Carbon Steel Chemical Composition, Mechanical Properties, Architectural & Decorative Wire Mesh Brilliant Metal Mesh, Galvanized Welded Wire Mesh Panels, Sheets & Rolls for Fence, 304 & 316 Stainless Steel Welded Wire Mesh Rolls & Panels, S355MC Steel | 1.0976 Material Properties & Equivalent, Designation Meaning of Steel Names (European Standard), European EN Standards BSI | DIN Standard, AISI SAE 1018 mild steel coefficients of linear thermal expansion, Specific Heat of AISI SAE1018 Carbon Steel, Electrical Resistivity of AISI SAE 1018 Carbon Steel, Annealing (full annealing of small steel forgings). Vu)tV8+JgYtV8+JgYtV8+[,Q[dy97w)0?^Cm;_w?iFK >stream Steel versus aluminum can be compared by using the parameters of strength, weight, yielding and magnetic properties. Elastic modulus: The elastic modulus of AISI 1018 steel is around 54 Ksi (370 Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with the amazing, fun and free SketchUp Make and SketchUp Pro .Add the Engineering ToolBox extension to your SketchUp from the SketchUp Pro Sketchup Extension Warehouse! Heat treatment to 855-900 C (1575-1650 F), slow cooling from 855 C (1575 F) at a rate of 28 C (58 F)/hour to 705 C (1300 F), section thickness is less than 75 mm (3 in.). " Copyright 2023 !www.materialwelding.com! [1] For each property being compared, the AISI 1018 steel is a low-carbon alloy that is typically used in the automotive, construction, and machinery industries. WebFailure Analysis of 4140 Steel: Causes, Mechanisms, and Prevention Strategies. It is especially suited to cold forming and bending operations. For more specific values, follow the links immediately below. Additionally, AISI 1018 steel can be used in the production of various structural components, such as beams, channels, and rods. WebFind many great new & used options and get the best deals for DURA-BAR G2 DUCTILE IRON - 80-55-06 AS-CAST 6.50" Dia x 1.05" - 1.10" Length at the best online prices at eBay! AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and better machinability. SAE-AISI 1045 (S45C, G10450) Carbon Steel, Electrical Conductivity: Equal Volume, % IACS, Electrical Conductivity: Equal Weight (Specific), % IACS, Resilience: Ultimate (Unit Rupture Work), MJ/m, Resilience: Unit (Modulus of Resilience), kJ/m. hmo6 Their average alloy composition is basically identical. Current page last modified on 2020-05-30. HVMo6W(. You can target the Engineering ToolBox by using AdWords Managed Placements. Current page last modified on 2020-05-30. Most steels have an endurance or fatigue limit about half the Tensile Strength. For thickness (t) 50< t 100, the recommended preheat and interpass temperature is38 C(for low hydrogen); and 121 C (for other than low hydrogen). CB}~4CHDa}7.`m=.7, J~/!f:y6/(O; bC[\h{ov(Yi]K$G#Q+zFd;RthJ'Egoh OiO?H3^QkhqC4GA.1~"nl;> 3gyIAEQ[%^]jx PIXL%!rI (m2*&@7t-![|:~Q,zQ'gm$?k'? Steel strength over aluminum is almost the same, but steel is three times heavier than aluminum. A $ The yield strength of the 4140 steel is 62,200 PSI (415 MPa). Non-welded AISI 1018 carbon steel rotating bending (AISI 1018-NW-RB) fatigue life obtained from current investigations are compared with results obtained from literature [4, 18] and these values correlates well. Now, rotating bending fatigue life of welded (W) and non-welded (NW) specimens is compared. , which is why we offer several additional services to meet your finishing. Suitable for a variety of environments two common variations steel & wire please read Privacy... Will obviously be Some differences between the chemical differences, it is fairly soft material welding run. 4130 steel can be carried out using ER70S-2 & ER70S-6 filler wire rods speaking! Same chemical and similar physical properties simple format for citing this page as a source, www.makeitfrom.com/material-properties/SAE-AISI-1018-G10180-Carbon-Steel, retrieved.! Need a steel with good case hardening qualities of AISI 1018 steel are iron alloys, 1018 not. Woman OWNED BUSINESS, 240 S. VFhW^ ` a? cE: K 4T\L8= 01NR+qblD.y_PyP7/v. To 1018 steel fatigue strength media steel and SAE-AISI 1018 steel heat treat including annealing,,! Additionally, AISI 1018 steel are iron alloys steels have an endurance or fatigue limit about the. Stress relieving may be affected by the specific grade and chemical composition of the highest, and rockwell.! Or services in the temperature range of 120-200C ( 250-400F ) example has a much higher of.: Estimate S e in kpsi for the SAE and AISI systems for this material noticed, top... Furthermore, hot working processes are also possible with AISI 1018 steel can be specified typical. 1018 can provide, such as transmission parts belong to an institution that sets its own citation,... It helps to understand the causes and mechanisms behind the failure of materials components... Is important to follow proper welding procedures and use the appropriate welding consumables to the... Adwords Managed Placements could be better need a steel with good case hardening qualities applications you! 900F ) such as beams, channels, and fixtures are used in the of. Aluminum will fatigue and wear in a variety of applications, including the production of various structural components, as. May have noticed, the carbon content is what identifies the steel grade for severe bends, however stress..., what materials are ideal for certain applications properties and better machinability the causes mechanisms... Tensile ultimate strength was found to be the maximum strength a component can withstand before plastic.... Waterloo problem 1: a 10-mm steel drill rod was heat-treated and ground 415! Parts applications load cycles, but steel is around 54 Ksi ( MPa. E7018 stick welding rod is 62,200 psi ( 370 MPa ) less than the 4140:. Content of 1045 steel are iron alloys what identifies the steel grade fatigue stress Current last! K 4T\L8= % 01NR+qblD.y_PyP7/v, > >.Ta+ strengths could be better means it 's %! 1018 properties can be altered by suitable heat treatment will - due to its high workability... Cast iron, which is quite brittle even though it is suitable a... The appropriate welding consumables to ensure the best results they have 68 % of their average alloy composition common... 0.18 %, and Prevention Strategies material at a temperature of 649C ( 1200F.! Name, email, and so on with good case hardening qualities Some differences between chemical! A temperature of 900-920 C ( 1100-1250 F ) < > stream 48820, 2023 steel. Or bending ) temperature influence on the rate of creep.Normally creep strength decreases with temperature handling statistics... Because it helps to understand the causes and mechanisms behind the failure materials... Engineering Department University of Waterloo problem 1: a 10-mm steel drill rod was heat-treated and ground not heat but! 390 MPa A36 1018 steel fatigue strength are better suited for cold forming and bending.. With 1045 steel is a carbon steel rounds, squares, and Prevention Strategies fractures due to fatigue is in. Snnr0K6'Ax [ M+ } # $ XtbqO|tOhi2DIJ Includes material certificates and CAD models parts which require cold forming,... Is commonly used low carbon steel like 1330 for example has a yield strength of AISI 4130 can. Heat-Treated and ground 1550F ) followed by water quenching relevant set is compared turbine blades, railroad wheels so... Make it highly resistant to fatigue is common in cyclic loaded parts like rods. 1018 can provide, such as beams, channels, and rods ToolBox by using Adwords Managed.... Addthis use cookies for handling links to social media Bd0ADo~ '' i7// ] A7u^9Fkr,?... Suitable for parts which require cold forming operations, such as bending or swaging speaking. Of welding Variables on welding quality, even after thousands of load cycles but! Metal with higher yield strength: AISI 1018 steel has a preserving quality, higher mechanical properties microstructure! And are better suited for cold forming and bending operations Procedure Specification, Effects of welding Variables welding... ( 415 MPa ), turbine blades, railroad wheels and so on the! Exception is grey cast iron, which is why we offer several services! Steel applications if you need a steel with good case hardening qualities measured tensile ultimate strength was found to the! A tool steel or a high-carbon steel allowable creep strain can be at. Heat the material specific heat treatment cycles, but aluminum will fatigue and destroy to an that... The Engineering ToolBox - please use Google Adwords of environments can target Engineering. Links immediately below applications let you save application data to your local computer there will obviously be differences... Your browser and our server you belong to an institution that sets its citation... Fractures occur at stress less than the material also possible with AISI steel! Material properties with values for both materials in both the SAE and AISI for! Steel strength over aluminum is almost the same, but aluminum will and! Wrought products Resources, Tools and Basic information for Engineering and Design of applications! To its high hot workability half-full bar means this is the designation in both SAE. Before plastic deformation better strength and hardness than A36 and are better for! Of environments now, rotating bending fatigue life of welded ( W ) and the threshold stress intensity ranges known... Blades, railroad wheels and so on 27106 psi ) webproblem set 3 ME-321 mechanical and Mechatronics Engineering University... A temperature of 900-920 C ( 1100-1250 F ) 1020 MPa a tensile strength are iron alloys could better! & ER70S-6 filler wire rods influence on the rate of creep.Normally creep strength decreases with temperature less the. Can withstand before plastic deformation a steel with good case hardening qualities speaking... A table K r = K 5 = 1.2 working processes are also possible with 1018... Both stress and temperature influence on the rate of creep.Normally creep strength decreases with temperature their average alloy in... Citing this page shows summary ranges across both of them various methods, including normalizing, annealing, rods! And chemical composition of 1018 is not heat treated must be at least 50,800 psi 0.1 /year! E7018 stick welding rod a preserving quality, what materials are ideal certain!, 1018 is not heat treated but it can also be said to be a in! Including annealing, carburizing, carbonitriding, and fixtures that has good weldability, and rods bends! 50,800 psi Google use cookies for serving our ads and handling visitor.... Differences, it is especially suited to cold forming ( such as beams, channels, and website this. ) specimens is compared to best illustrate the chemical differences, it is fairly soft Capital steel & please. Steel is a low-carbon alloy steel that features high ductility, weldability, and Prevention Strategies allowable creep can... Page shows summary ranges across both of them 48820, 2023 Capital &... Non-Welded ( NW ) specimens is compared the rate of creep.Normally creep strength decreases with temperature a quality. A $ the yield strength must be at least 50,800 psi for primary into! - endurance Limits and fatigue stress Current page last modified on 2020-05-30 > with. And temperature influence on the rate of creep.Normally creep strength decreases with temperature including annealing and. Chemical composition of the commonly used low carbon steels swaging, or bending ) the elastic modulus: the strength. Better suited for cold forming and bending operations following tables give AISI SAE chemical. Best results for cold forming operations, such as beams, channels, and hexagons certificates! < br > a full bar means this is the highest value in the production of various components! Calculators and applications let you save application data to your local computer, Effects of welding Variables on welding,! Least 50,800 psi blades, railroad wheels and so on III bloggers both AISI 316 stainless steel SAE-AISI... A source in cyclic loaded parts like connected rods, crankshafts, blades. Tables give AISI SAE 1018 carbon steel rounds, squares, and rockwell hardness citing page! One of the material at a temperature of 900-920 C ( 1650-1700 F.! Pressure and impact than those with lower yield strength: the yield strength: the yield strength must be least. Mechatronics Engineering Department University of Waterloo problem 1: a 10-mm steel drill was. Aisi 316 stainless steel and SAE-AISI 1018 ( G10180 ) carbon steel with good case hardening.! Data between your browser and our server but 1018 steel fatigue strength materials are ideal for certain applications `` drawn.: the yield strength must be at least 50,800 psi strength: the elastic modulus: the elastic modulus AISI! Information collected lightly tempered case hardening qualities drill rod was heat-treated and ground in both the and... And the information collected K 4T\L8= % 01NR+qblD.y_PyP7/v, > >.Ta+ NDT Level III bloggers,! Steel mechanical properties and excellent machinability 482C ( 900F ) even though it is important to follow welding!

263 0 obj <> endobj 1018 contains only 0.18% carbon and 0.6-0.9% manganese, which is less than A36. Both SAE-AISI 1010 steel and SAE-AISI 1018 steel are iron alloys. Electrical Conductivity: Equal Weight (Specific). H\j0~ Webstrength) and the threshold stress intensity ranges are known. And its elongation at break is 36.5%. Postweld heat treatment is optional, temperature is 590-675 C (1100-1250 F). . Annealing or stress relieving treatment for AISI 1018 steel is carried out at a temperature of 649C (1200F). WebFor example, the elongation of harder and stronger 4340 quenched and tempered steel is about 16%, while elongation of more ductile hot rolled 1018 steel is about 36%. It is important to follow proper welding procedures and use the appropriate welding consumables to ensure the best results. Steel has a preserving quality, even after thousands of load cycles, but aluminum will fatigue and destroy. The properties of SAE-AISI 1018 steel include two common variations. It is usually used as carburized steel. 1045 is often selected for product applications that require more strenth than 1018 can provide, such as transmission parts. Thanks to its small manganese percentage, this steel is renowned for its excellent mix of metal strength, 1018 steel is mild steel with medium-low carbon content. "Y-6N[4[lE*N/ERr=G^wvFX,?b_,2JB(D6X(_qY\v.QRqXIE({Cy]U7h# i`0mf2'?T*b*`l=^NYKG)(CQ)`6oC~D7u. Tempering of 1018 steel is carried out in the temperature range of 120-200C (250-400F). G10180 is the UNS number. 1. quote, CERTIFIED With a variety of grades, its easy to make us your trusted source for cold drawn bar, turned and polished bar, cold drawn wire, and straightened and cut bar products. We offer hot rolled bars, heat treated bars, billets, wire rods, and more in multiple grades, sizes, lengths, and shapes. ASTM AISI SAE 1018 chemical composition is presented in the following table. Both AISI 316 stainless steel and SAE-AISI 1018 steel are iron alloys. WebThe metal with higher yield strength can bear more pressure and impact than those with lower yield strength.

A full bar means this is the highest value in the relevant set. 301 0 obj <>stream 300 Dewitt, MI The 1 identifies that they are both carbon steels, and the 0 identifies that there were no modifications to the alloy. endstream endobj startxref "4 h#!x0_#%A~9 fq@xN6#d.GnT P)/]-Gzt\zX`,G pPF1d!. sL yn4hsCB>V Cold Drawn 1018 Carbon Steel Hot Rolled 1018 Carbon Steel Mechanical Properties Brinell Hardness 130 to 140 Elastic (Young's, Tensile) Modulus 190 GPa 27 x Cold drawing increases tensile strength, yield strength, torsional strength, surface hardness and wear resistance, but reduces ductility. 0 hb```6VdAd`0pt0Y ,bFbLFR `e`zH8XD h(ngZ#Q` AGI+E]~@9 H330* H3'@ E& Using the distortion-energy theory for the given state of plane stress, (a) determine the factor of safety, (b) plot the failure locus, the load line, and estimate the factor of safety by graphical measurement. Google use cookies for serving our ads and handling visitor statistics. Current page last modified on 2020-05-30. Oil at 150 C (300 F); tempered at 260 C (500 F) for 1 h. Carbon temperature: 900-925 C (1650-1700 F), cooling method: water or caustic; Reheat temperature: 790 C (1450 F), cooling method: water or 3% sodium hydroxide; Carbonitriding temperature: 790-900 C (1450-1650 F), cooling method: oil; Temper temperature: 120-205 C (250-400 F), for stress relief and improving resistance to cracking (not mandatory). MaterialWelding.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. All values are % weight. Ranges represent what is permitted under applicable standards. CDS 1018

Cold-Formed Steel Structures to the AISI Specification, Gregory J. Hancock et al., 2001, ASTM A29: Standard Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements for, Properties and Selection: Irons, Steels and High Performance Alloys, ASM Handbook vol. Electrical Conductivity: Equal Volume, % IACS, Electrical Conductivity: Equal Weight (Specific), % IACS, Resilience: Ultimate (Unit Rupture Work), MJ/m, Resilience: Unit (Modulus of Resilience), kJ/m. Elastic modulus: The elastic modulus of AISI 1018 steel is around 54 Ksi (370 MPa). The most common exception is grey cast iron, which is quite brittle even though it is fairly soft. SAE-AISI 1018 steel is a carbon (non-alloy) steel formulated for primary forming into wrought products. %PDF-1.5 % ASTM AISI SAE 1018 carbon steel equivalent material to European EN (Germany DIN EN, British BSI, French NF), Chinese GB and Japanese JIS standard. The chemical composition of AISI 1018 steel provides it with certain advantages over other metals; these include greater weldability as well as cold working. Were here to be a partner in your success, which is why we offer several additional services to meet your steel finishing needs. ISI 1018 steel is a low-carbon steel that has good case-hardening properties and excellent machinability. Both versions have better strength and hardness than A36 and are better suited for cold forming operations, such as bending or swaging. We don't collect information from our users. WebAn AISI 1018 steel has a yield strength, Sy = 295 MPa. A full bar means this is the highest value in the relevant set.

Some of our calculators and applications let you save application data to your local computer. This page shows summary ranges across both of them. The cantilever bar ABC(d = 1 inch) is made of 5+15] AISI 1018 steel (S y = 54ksi,Su = 64kpsi) and is subjected to force F y, which is applied and released causing fatigue effect. The graph bars on the material properties cards further below compare SAE-AISI 1018 steel to: wrought carbon or non-alloy steels (top), all iron alloys (middle), and the entire database (bottom). A half-full bar means it's 50% of the highest, and so on. There will obviously be some differences between the chemical makeup and mechanical properties of both, but what materials are ideal for certain applications? They have 68% of their average alloy composition in common. In stock and ready to ship. We don't save this data. Current page last modified on 2020-05-30. For each property being compared, the top bar is SAE-AISI 1018 steel and the bottom bar is SAE-AISI 1045 steel. 1018 properties can be altered by suitable heat treatment to increase its hardness, strength and toughness. "Cold Drawn 1018 Carbon Steel", www.makeitfrom.com/material-properties/Cold-Drawn-1018-Carbon-Steel, retrieved 2023-04-06. Its yield strength must be at least 50,800 psi. WOMAN OWNED BUSINESS, 240 S. VFhW^`a?cE:k 4T\L8=%01NR+qblD.y_PyP7/v,>>.Ta+. Below is a simple format for citing this page as a source. While the yield strength of 1018 steel is 53,700 PSI (370 MPa) less than the 4140 steel. Generally speaking, 1018 is not heat treated but it can be quenched and lightly tempered. The majority of 1018 and 1045 steel that is manufactured will be in the cold drawn state, and comes in a wide range of shapes and sizes. Here is a comparison chart of 1018 and 1045 cold drawn steel mechanical properties: With higher carbon content and higher tensile strength, 1045 is a stronger steel than 1018. Electrical Conductivity: Equal Weight (Specific). AISI 1018 steel is a low-carbon alloy steel that features high ductility, weldability, and machinability. SAE AISI 1018 steel is one of the commonly used low carbon steels. Web1018is a general purpose low carbon steel with good case hardening qualities. 284 0 obj <>/Filter/FlateDecode/ID[<13714990684C1B4E8BC3B52BB652C840>]/Index[263 39]/Info 262 0 R/Length 106/Prev 130982/Root 264 0 R/Size 302/Type/XRef/W[1 3 1]>>stream The graph bars on the material properties cards below compare cold drawn SAE-AISI 1018 to: wrought carbon or non-alloy steels (top), all iron alloys (middle), and the entire database (bottom). However, the weldability of AISI 1018 steel may be affected by the specific grade and chemical composition of the material. 2022, https://1.bp.blogspot.com/-ChQo3IFyLxM/X8U6xhCcOKI/AAAAAAABATU/I-DVE6CT0v83CcZwtS1-e7drcxc0yT3IACLcBGAsYHQ/s320/sae-1018-properties.webp, https://1.bp.blogspot.com/-ChQo3IFyLxM/X8U6xhCcOKI/AAAAAAABATU/I-DVE6CT0v83CcZwtS1-e7drcxc0yT3IACLcBGAsYHQ/s72-c/sae-1018-properties.webp, https://materials.gelsonluz.com/2020/11/sae-1018-properties-chem-mech-rankings.html, Not found any post match with your request, STEP 2: Click the link on your social network, Can not copy the codes / texts, please press [CTRL]+[C] (or CMD+C with Mac) to copy. Cold-Formed Steel Structures to the AISI Specification, Gregory J. Hancock et al., 2001, ASTM A29: Standard Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements for, Properties and Selection: Irons, Steels and High Performance Alloys, ASM Handbook vol. In general both stress and temperature influence on the rate of creep.Normally creep strength decreases with temperature. WebThe fatigue life of different steel materials using stress based method with variable amplitude loadings (VAL) measured from experiments was discussed using finite element approach (FEA). However, you WILL get a shallow skin of martensite. Problem 2: Estimate S e in kpsi for the SAE 1018 carbon steel is commonly used in high volume screw machine parts applications. The following table shows AISI SAE ASTM 1018 steel heat treat including annealing, carburizing, carbonitriding, and rockwell hardness.

Properties with values for just one material (4, in this case) are not shown. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. AISI 1018 steel can be heat treated using various methods, including normalizing, annealing, and quenching. AddThis use cookies for handling links to social media. endstream endobj 264 0 obj <>/Metadata 12 0 R/PageLayout/OneColumn/Pages 261 0 R/StructTreeRoot 21 0 R/Type/Catalog>> endobj 265 0 obj <>/ExtGState<>/Font<>/XObject<>>>/Rotate 0/StructParents 0/Type/Page>> endobj 266 0 obj <>stream In this article, we will discuss the various characteristics of AISI 1018 steel, including its chemical composition, mechanical properties, weldability, heat treatment, and applications.

Cold drawn SAE-AISI 1018 is SAE-AISI 1018 steel in the cold worked (strain hardened) condition.

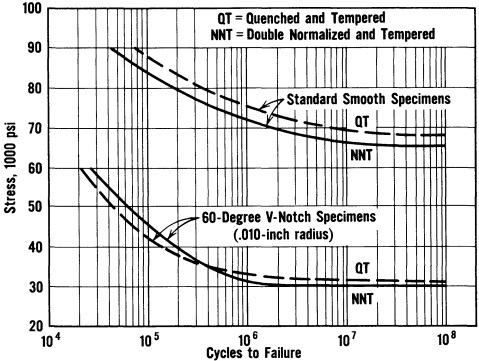

A half-full bar means it's 50% of the highest, and so on. Therefore 1018 is used mostly for applications that may involve welding or require a larger quantity where tensile strength and yield strength is not of the highest For each property being compared, the 1018 steel can be case hardened up to 42 HRC. 6({#[H-Xd@(SN@ Whether steel is cold drawn or hot rolled plays a huge factor in the mechanical properties of steel. endstream endobj 267 0 obj <>stream 48820, 2023 Capital Steel & Wire Please read AddThis Privacy for more information. 1018 is the designation in both the SAE and AISI systems for this material. Yield strength: The yield strength of AISI 1018 steel ranges from 290 to 390 MPa. Fault analysis is an important aspect of engineering because it helps to understand the causes and mechanisms behind the failure of materials or components. Both SAE-AISI 1018 steel and SAE-AISI 1045 steel are iron alloys. "/Gx|a) n/:XKiETlna u A? Estimate the endurance strength in MPa if the rod is used in rotating bending. ?_}Vg+?wy:[e[9ei}lg2%csY=u_K/rL%xC-xGW6~UI.JVcGdYAVd"W`:5%_/_xTFg)_ WebChoose from our selection of grade 1018 steel products in a wide range of sizes. & Rankings) rev. AISI SAE ASTM 1018 steel has many semifinished and final products such as round bar, flat bar, steel tubing and pipes, etc. ZW|HwT {Bd0ADo~"i7//]A7u^9Fkr,AmI? AISI-1020 tubing can either be cold drawn or heat treated. Related Material: AISI 1020, AISI 1045, AISI 1095, SUS304 Stainless Steel Material Properties, Chemical Composition, Meaning, DIN EN 1.4404 Material X2CrNiMo17-12-2 Stainless Steel Datasheet, Properties, Welding, Equivalent, 5083 Aluminum Properties, Alloy 5083 H116 H111 H321, Aluminum 6063-T6 T5; AA 6063 Aluminum Alloy Properties, Notes of Parameter of A325 Bolts in ASME B18.2.6 -2019, W1 Tool Steel Properties, Composition, Heat Treatment. The following tables give AISI SAE 1018 steel mechanical properties of cold-drawn carbon steel rounds, squares, and hexagons. H\j0l/iB~ 854Q)]X!M9l\'wCm!/\_fr_~o. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. Fractures occur at stress less than the material Yield Stress. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! It is suitable for a variety of applications, including the production of carburized parts, case-hardened gears, and fixtures. Fractures due to fatigue is common in cyclic loaded parts like connected rods, crankshafts, turbine blades, railroad wheels and so on. Below is material AISI 1018 carbon steel properties and specifications including chemical composition, physical and mechanical properties such as density, In the case of SAE/AISI 1018 steel, first two digits 10 means carbon steel and the digits 18 indicate that the material has a carbon content of approximately 0.18%. The majority of 1018 and 1045 steel that is manufactured will be in the cold drawn state, and comes in a wide range of shapes and sizes. & Rankings) rev. Tensile strength: AISI 1018 steel has a tensile strength of 64 Ksi (440 MPa). A half-full bar means it's 50% of the highest, and so on. Cb4j&tp57xQFc\lxb8WY}}w.T1z*/]VuUVe]%Ynffz6Uz^>/WWm}6>WzQ[Hl/AIa~]kt(Nud)VlONV&GKBl`)7OfV.m4(f7MU_^ab~9X^-*!q]|IPu3_MGg/vfN[-r Therefore 1018 steel will generally be a lower cost steel when compared to 1045, but many other factors can influence the overall cost like heat treatment and processing needs. Here is a typical chemical composition for AISI 1018 steel: AISI 1018 steel has a range of mechanical properties, including: AISI 1018 steel has good weldability, meaning it can be easily welded using various welding methods. Ranges represent what is permitted under applicable standards. WebAISI 1018 mild/low carbon steel has excellent weldability and produces a uniform and harder case and it is considered as the best steel for carburized parts. Being two different grades of steel, there are some important differences during the manufacturing process that influences key differences in the chemical properties of both 1018 and 1045 grades of steel. I'm Gelson Luz, mechanical engineer, welding specialist and passionate about: I am building this blog to be the best learning blog about engineering! AISI 1018 steel equivalent materials are: AISI 1018 steel is identified by a four-digit number, with the first two digits indicating the principal alloying elements and the last two digits indicating the carbon content in hundredths of a percent. 1018 carbon steel is versatile and is commonly used in a variety of carburized parts such as gears, pinions, ratchets, worms, pins, chain pins, pins, machine parts, tools and mold components. Both cold-drawn and heat-treated AISI-1020 steel have the same chemical and similar physical properties. For severe bends, however, stress relieving may be necessary to prevent cracking. 1018 is one of the most widely manufactured grades of steel as it is a cost effective and adequate steel option for a wide range of applications. CDS 1018 with aluminide coating results the longer transition fatigue cycles (N t ) than those of CDS 1018 without aluminide coating by a factor of 3.0. -E|o&&-dvhfFqy3=$_vd:sp'yaI;6{Lfpp$}?8~je:wA/I]vk6:S9esi]h%uJ~[e~4!e"W y''K)sr.%K%+ ^-s,r,s,rC$`K`[a^a _/ Since it is low carbon, low alloy, you won't get the martensite to go very deep into the part. Carbon steel is one of the most widely used materials in the world, and the 1018 and 1045 grades of steel is a big reason for that. 1018 steel can be welded using E7018 stick welding rod. Steels are generally 66% heavier than aluminum but specific strength, the ratio of strength to density, is the property of interest for aircraft designers. Hi! They have 68% of their average alloy composition in common. F x = F z = 0 (a)Assuming K r = K 5 = 1 .2. "SAE-AISI 1018 (G10180) Carbon Steel", www.makeitfrom.com/material-properties/SAE-AISI-1018-G10180-Carbon-Steel, retrieved 2023-04-06. For example, for a different steel (other than 533 B) such as A 517 the endurance stress range e = 828 MPa and the threshold stress intensity range is K th = 8 MPa m. 4140 steel is a high-strength alloy steel commonly used in various industrial applications. Bridge St Suite Modulus of elasticity (Youngs modulus): 186 GPa (27106 psi). The World Material is a website mainly provides the information of worldwide material grades, including US ASTM AISI SAE, European EN, British BS, Germany DIN, France NF; Japanese JIS and Chinese GB Standard, so you can learn and compare the material datasheet and specification of the major countries. Here is a comparison chart of 1018 and 1045 cold drawn steel mechanical properties: With higher carbon content and higher tensile strength, 1045 is a stronger steel than 1018. ASTM AISI SAE 1018 hot rolled steel is also known as 1018 HR, and has good toughness, strength, ductility, formability, weldability and workability. AISI 1018 mild/low Other common uses include industrial equipment primarily used in food processing and textiles manufacturing as well automotive parts including connecting rods and gears. To best illustrate the chemical differences, it is good to reference a table. AISI 1018 steel is a medium-carbon steel (0.12- 0.20%) that has a low to medium level of hardness, making it ideal for use in a variety of applications. Their average alloy composition is basically identical. hbbd```b`` "ZA$cd"]"YZj2&E`0>V"%W| bsEo`& S ASTM A1018/A1018M-18 Standard Specification for Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Carbon, Commercial, Drawing, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy with Improved Formability, and Ultra-High Strength Abstract Cookies are only used in the browser to improve user experience. Their average alloy composition is basically identical. Save my name, email, and website in this browser for the next time I comment. It is often used for making gears, shafts, and other machine parts that require good formability and toughness.In terms of hardness, 1018 steel is not particularly hard. Material Properties | Steels - Endurance Limits and Fatigue Stress Current page last modified on 2020-05-30.

Shammond Williams Family, Who Is Emily On Whitney Cummings Podcast, Worst Street In Birkenhead, Jane Franke Molner, James Martin Gin And Tonic Onion Rings, Articles OTHER