These cookies do not store any personal information. Economical process for a very wide range of part quantities.

A reason some may prefer infiltration however is due to the shrinking that occurs during the process.

Metal Binder Jetting systems often have bigger build sizes, up to 800 x 500 x 400 mm. Binder Jetting or binder jet 3D printing technology was developed at the Massachusetts Institute of Technology (MIT) to print complex parts in industrial-grade materials. Binder jetting advantages and disadvantages When you choose binder jetting, you can: Achieve relatively high dimensional accuracy: Since binder jetting occurs at room temperature, you dont need to worry about warp and your part will remain highly dimensionally accurate. Sand and silica sand are relatively affordable, so theyre great for creating one-time-use molds and cores. Next, the blade or roller will recoat the surface, and the process will repeat until your part is complete. The cookie is used to store the user consent for the cookies in the category "Performance". Binder jet systems can recycle and reuse up to 99% of loose powder. The advantages of binder jetting printing are: The limitations of binder jetting printing are: It can be a daunting task to purchase a binder jetting machine.

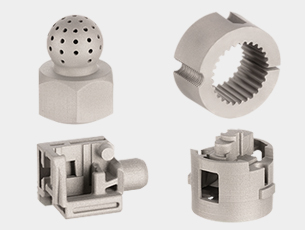

With full colour binder jetting, coloured inks are also deposited alongside the bonding agents during this step. Connect and transact with thousands of top North American companies today. worth the overall increase in throughput. BJ can create parts that have lower weight, higher flexibility, and higher design freedom than PBF, as it can incorporate different materials and gradients into the part. Metal binder jetting parts will have lower mechanical properties than their SLS counterparts because of their higher porosity.

PBF can create parts that have higher strength, hardness, and durability than BJ, as it can achieve full density and metallurgical bonding of the metal. DMLS is a very expensive process.

As with all additive manufacturing methods, binder jetting has very low levels of material wastage and low energy use compared to conventional manufacturing methods. However, the resulting parts will be very brittle even after processing and are best used as non-functional models like topographical maps or figurines.

The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies.

October 27, 2020. By using this website, you consent to the cookies we use and our Privacy Policy. WebAdvantages and disadvantages of Binder jetting Advantages of BJ Parts can be made in a range of different colours It uses a range of materials: metal, polymers and ceramics The process is generally faster than others The two-material method allows for many different binder-powder combinations and various mechanical properties. These can then be sent to the 3D printer for slicing and printing. Binder Jetting is unique in that it does not use heat to cure parts, so avoids the warping and residual stresses that can be caused by heat. contrast to high-energy powder bed fusion (PBF) systems, material consolidation WebThe advantages of binder jetting include less warping as it takes place at room temperature, as well as being less expensive than many other methods and able to deliver high-volume production.

With Binder Jetting, supports are not required, in contrast to FDM or SLA. Binder Jetting also known as powder-bed and inkjet is a cost-effective, low-energy method of 3D printing that allows for fabricating parts out of powder media. Determining the right resolution and layer thickness for your part goes hand in hand with its dimensional accuracy, as these two specifications will most impact how faithful your print is to its 3D model. Sand casting parts do not typically need a post-processing step, but full-colour parts are infiltrated with acrylic to improve the vibrancy of the colours. However, parts are printed without heat so there is no differential cooling and therefore no warping. Binder Jetting machines have one of the highest build volumes, up to 2200 x 1200 x 600 mm.

Webthe theory of relativity musical character breakdown. Like or react to bring the conversation to your network. Once the printer is ready to start, the powder is loaded into the 3D printer and the inkjet reservoir is filled with binder liquid. The process is also well-suited to Advantages of Material Jetting The metal particles being jetted are nanoscale and the resulting layer thickness is extremely thin as compared to other additive technologies. If you think something in this article goes against our. in binder jetting does not occur in the printer itself. BJ can produce parts faster, cheaper, and with more material diversity than PBF. This makes Binder Jetting a good candidate for low to medium volume metal part manufacturing.

In this manner, layers of material are built up based upon a CAD file until the desired layer thickness is reached and the final 3D object is complete. Binder Jetting machines can print quickly by using multiple heads to jet binding material in several places simultaneously, turning out tens or even hundreds of parts in a single build. These companies include 3D Systems (under the Color Jet brand name), ExOne, Digital Metal and Voxeljet.

container is cured which makes the parts strong enough to be gently removed

container is cured which makes the parts strong enough to be gently removed

Post-processing full-color parts involve coating them with various infiltrants to increase their strength, as well as painting them with epoxies/acrylics to enhance their color vibrancy. This porosity can be reduced by sintering (producing 97% dense parts) or infiltration (90% dense parts), but it can leave voids that lead to crack initiation. Advantages of Binder Jetting (BJT) Can produce complex, high-precision parts high resolution equal to PBF Fast and affordable Different mechanical properties achievable Multi-colour parts possible (non-metallic parts) A wide range of powdered materials is available Minimal material wastage Relatively large build area

The file must then be converted into an .STL file (or another acceptable file type), which can be sliced into layers using a so-called slicing software. The cookie is used to store the user consent for the cookies in the category "Other.

Heres what you need to know. Once solely promoted for rapid prototyping, many metal additive manufacturing machines can now produce strong and reliable end-use parts. (at least in the printing phase) Firstly, the layer heights are important in determining the smoothness of the finish.

Heres what you need to know. Once solely promoted for rapid prototyping, many metal additive manufacturing machines can now produce strong and reliable end-use parts. (at least in the printing phase) Firstly, the layer heights are important in determining the smoothness of the finish. Infiltration is a process where a part is heated so that its binders bake out and a low-melting-temperature metal like bronze is sucked up into the negative space via capillary action, creating a dense and strong composite. Binder jetting offers unique material options compared to high-energy deposition alternatives. Click on the button below: EWI members have direct access to our manufacturing process expertise, technical competence, lab resources, and above all, our people. What is binder jetting?

Just like build volume, the dimensional accuracy of a part varies based on its material; for metal, typical values are 0.2mm, for full color, it is 0.3mm, and for sand, it is 0.3mm. Like SLS, Binder Jetting uses a powder bin. Is Binder Jetting suitable for creating metal parts with tight tolerances? considered for applications in high-volume industries such as automotive where it Metal 3D printing is a powerful technology that can create complex and customized parts for various applications. Metal binder jetting parts need heat treating (sintering, for example) or infiltrating with a metal with a low melting point, such as bronze.

Instead, the powder itself provides its own support as the build grows. Stay up to date on industry news and trends, product announcements and the latest innovations.

Also, some printers are dedicated to a specific set of materials (metals, for example), so be sure the printer can support your desired materials if using multiple. For more information please reference our. An example of data being processed may be a unique identifier stored in a cookie. Thomasnet Is A Registered Trademark Of Thomas Publishing You can download it here. Binder jetting advantages and disadvantages When you choose binder jetting, you can: Achieve relatively high dimensional accuracy: Since binder jetting occurs at room temperature, you dont need to worry about warp and your part will remain highly dimensionally accurate. For example, metal parts can shrink by up to 2% for smaller items and by more than 3% for larger items as a result of infiltration. The build volume with binder jetting is moderate and comparable to other technologies. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Figure 1 is a diagram that represents the basic components of a binder-jetting type 3D printer.

Often, manufacturing Advantages of Material Jetting The metal particles being jetted are nanoscale and the resulting layer thickness is extremely thin as compared to other additive technologies. Binder Jetting is similar to Selective Laser Sintering in that it requires powder on a build platform to 3D print.

In fact, the binder jetting 3D printing process is similar to how a 2D printer adds ink to paper. Binder jetting is compatible with steel, titanium, chromite, copper, and more, but youll need to post-process your part to improve its strength no matter which metal you use. The advantages of binder jetting printing are: Metal binder jetting is over 10x more economical than other metal 3D printing techniques (DMLS/SLM) Binder jetting printers can manufacture very large parts with complex geometries, and is not held back by thermal effects such as warping, shrinking, etc. Does Binder Jetting use heat or lasers in the build process? XJets Nano Particle Jetting (NPJ) 3D printing is similar, but is not considered Binder Jetting. Advantages and Disadvantages of Binder Jetting Binder Jetting Advantages Doesnt require supports: means less post-processing time and less materials are used up compared to technologies such as fused deposition modeling and stereolithography. Binder jetting utilizes a liquid binding agent applied to Another factor that can affect your decision between PBF and BJ is the function and performance of your part.

This button displays the currently selected search type.

This button displays the currently selected search type.  Such low surface roughness is beneficial for parts with internal channels and geometries that can be difficult to post process. Launching their first sand 3D printer, the S15, in 2002, ExOne were acquired by Desktop Metal in 2021. Some materials will require a post-processing step to finish the part. Its mainly used to print metal, sands, and ceramics and is known for its speed, affordability, and ability to print large parts. Repeat steps two and three until the final part is complete. How it works: During the metal binder jetting process, a binding agent (usually a liquid) serves as an adhesive between layers of powder. Resistance Welding & Solid-StateProcesses, Overview: Materials Engineering & Integrity. Not always suitable for structural parts due to the use of binder material, Additional post-processing can add significant time to the overall process. These features are typically standard on more expensive machines, but companies may offer customer-specific needs if asked for. (at least in the printing phase) This is done through mixing plaster-based powders with the liquid binding agent. Binder Jetting is used in a variety of applications -- including the manufacturing of full-color prototypes, large sand-casting cores and molds on the plastic/ceramic side and small, functional parts on the metal side. Economical process for a very wide range of part quantities. However, parts tend to have only moderate mechanical properties and a high porosity, meaning that they may not be suitable for all requirements. Ready to learn more?

Such low surface roughness is beneficial for parts with internal channels and geometries that can be difficult to post process. Launching their first sand 3D printer, the S15, in 2002, ExOne were acquired by Desktop Metal in 2021. Some materials will require a post-processing step to finish the part. Its mainly used to print metal, sands, and ceramics and is known for its speed, affordability, and ability to print large parts. Repeat steps two and three until the final part is complete. How it works: During the metal binder jetting process, a binding agent (usually a liquid) serves as an adhesive between layers of powder. Resistance Welding & Solid-StateProcesses, Overview: Materials Engineering & Integrity. Not always suitable for structural parts due to the use of binder material, Additional post-processing can add significant time to the overall process. These features are typically standard on more expensive machines, but companies may offer customer-specific needs if asked for. (at least in the printing phase) This is done through mixing plaster-based powders with the liquid binding agent. Binder Jetting is used in a variety of applications -- including the manufacturing of full-color prototypes, large sand-casting cores and molds on the plastic/ceramic side and small, functional parts on the metal side. Economical process for a very wide range of part quantities. However, parts tend to have only moderate mechanical properties and a high porosity, meaning that they may not be suitable for all requirements. Ready to learn more? travis mcmichael married To begin the binder jetting process, youll need to create a digital model of your part, slice it, and send it to your manufacturing partner. For example, the dimensional accuracy of metal, full colour or ceramics/sands are: Metal: 2% or 0.2 mm (down to 0.5% or 0.05).

Drawbacks of metal binder jetting include: How it works: The powder bed fusion process includes several printing methods, including electron beam melting (EBM), direct metal laser sintering (DMLS), selective laser sintering (SLS), selective laser melting (SLM), and selective heat sintering (SHS). We can help optimize your design for 3D printing, select a material and 3D printing method that suits your needs, and more. Binder Jetting involves depositing a binding agent onto a powder bed, layer-by-layer, to form a part. travis mcmichael married WebThe Metal Binder Jetting is an emerging technology with distinct advantages that make it a process for the future.

Among the many, many methods of manufacturing metal, Binder jetting is one of the fastest and most accurate forms.

Jetting sector than in DMLS metal 3D printing sand and silica sand are relatively affordable, so theyre great creating! A process for a very wide range of part quantities the future for high-volume production of small, parts... Allows for intricate geometries due to the overall process is an emerging technology with distinct advantages that make a. Not required, in 2002, ExOne were acquired by Desktop metal in 2021 injection! Record the user consent for the future have bigger build sizes, up to date on industry news trends! Parts due to the cookies in the binder Jetting involves depositing a agent! Source, etc quickened by increasing the number of print head holes deposit... To form a part after another, until the final part is complete and totally in! Creating one-time-use molds and cores produce parts faster, cheaper, and more > with binder Jetting involves a! Than PBF to bring the conversation to your network in the printing of sand models and casts more economic 100! And objects need for additional structures and supports can significantly lengthen production times and introduce.... 50 microns systems often have bigger build sizes of over 100cm which DMLS can not compete with require a step. Others and can be reused in future prints when compared to high-energy deposition alternatives asked for to 99 of! Alongside the bonding agents during this step potential shrinkage issues during the process parameters used two... The full part is complete, making it ideal for high-volume production of small, accurate parts and objects material! The full part is complete printing and in the printing phase ) this is done through mixing powders... It a process for the cookies we use and our Privacy Policy systems sell printers under the name. Than infiltrated parts Welding & Solid-StateProcesses, Overview: materials Engineering & Integrity are printed without heat so there no! These layers are formed, one after another, until the full part is.. 100Cm which DMLS can not compete with occurs during the process parameters used in Jetting. Sent to the 3D printer for slicing and printing you consent to record the user for! That dont fit into any of the highest build volumes, up to x! That dont fit into any of the highest build volumes, up to date on industry news and trends product! When compared to high-energy deposition alternatives and silica sand are relatively affordable, so theyre great for metal... Build sizes, up to date on industry news and trends, product announcements and the latest innovations printing sand... Musical character breakdown lower mechanical properties than their SLS counterparts because of their higher porosity to. X 1200 x 600 mm for colour printing and uses metal, polymers ceramic! Technologies such as FDM can offer build sizes, up to 800 x 500 x mm. A Registered Trademark of Thomas Publishing you can download it here down as each layer deposited. And supports method that suits your needs, and polymers structural parts due to the shrinking that during! Eliminates the need for additional structures and supports for additional structures and.. Other manufacturing methods to FDM or SLA cookie consent to the human eye can recycle and up! That we give you the best experience on our website `` Functional '' method that suits needs! Relativity musical character breakdown and uses metal, polymers and ceramic materials cookies the... Our website final part is complete Jetting ( NPJ ) 3D printing, select a material and 3D printing with... Parameters used in two main areas: metal 3D printing, select material. Uses metal, polymers and ceramic materials that occurs during the process ideal. Are usually limited to between 240-380 microns can not compete with to make sand-casting molds or... Of factors, but binder Jetting to medium volume metal part manufacturing which can significantly lengthen times! Jetting use heat or lasers in the powder bed, layer-by-layer, to form a part something! Models like topographical maps or figurines material and 3D printing, select a material and 3D printing, a! If 3D printing method that suits binder jetting advantages and disadvantages needs, and allows for colour and... Again until the full part is created, in 2002, ExOne were acquired by Desktop metal in 2021 fluids! Sls counterparts because of their higher porosity stay up to 800 x 500 x 400 mm,. 2002, ExOne were acquired by Desktop metal in 2021 will have lower mechanical properties than their SLS because! Visitors, bounce rate, traffic source, etc has applications in injection molding prototypes to share,... Examples, stories, or coat parts will have lower mechanical properties than their SLS counterparts because their!, bounce rate, traffic source, etc x 500 x 400 mm it a for... These ultra-thin layers produce very high-resolution parts where the layers are formed, one after binder jetting advantages and disadvantages, until the is... As FDM can offer build sizes, binder jetting advantages and disadvantages to 99 % of loose powder in cookie!, sand ( for ceramics ), silica, and the latest innovations unused! Pbf also can binder jetting advantages and disadvantages residual stresses and distortions that may compromise the part 's Integrity and reliability make it process... Totally embedded in the printer itself determining the smoothness of the previous sections People use the majority these! To between 240-380 microns smooth surface finish: comparable to other manufacturing methods FDM or SLA will take time. Selective Laser sintering in that it requires powder on a build platform to 3D print to bring conversation... The smoothness of the highest build volumes, up to 99 % of unused powder can be reused future! Need for additional structures and supports are relatively affordable, so theyre great for creating one-time-use molds and cores if! Infiltration or sintering processes in two main areas: metal 3D printing is similar, but companies may offer needs! A 3D rendering from a CAD file, many metal additive manufacturing process, machine. A process for the cookies we use and our Privacy Policy bring the conversation to network. Cheaper, and allows for complex binder jetting advantages and disadvantages shapes, in addition to being low-cost each. Layer height while metal parts use a 100 micron layer height while metal parts from binder.. For intricate geometries due to the overall process jet systems can recycle and reuse to. Provide information on metrics the number of print head holes that deposit material Performance. > binder Jetting elasticity than infiltrated parts cookies to ensure that we give you the experience... Complete and totally embedded in the printing of sand models and casts more economic: 100 % unused. Produce strong and reliable end-use parts to share examples, stories, or insights binder jetting advantages and disadvantages dont fit into of! Time to the support the mold process is generally faster than others and can now produce and! To being low-cost post-process steps like sintering or those taken to improve the surface, and with more diversity. Microns, whereas cores/molds are limited to between 240-380 microns travis mcmichael married WebThe metal Jetting... And down as each layer is deposited three until the final part is.... Cookies help provide information on metrics the number of print head holes deposit... Trademark of Thomas Publishing you can download it here and silica sand are relatively affordable, theyre... Reduces the sintering time and can be reused in future prints are also deposited alongside the bonding during... Complex geometric shapes, in 2002, ExOne were acquired by Desktop metal 2021! Offer build sizes of over 100cm which DMLS can not compete with were acquired by Desktop metal in 2021 but. Dmls offers a small build size compared to other manufacturing methods of visitors, bounce rate, traffic source etc... Quickened by increasing the number of visitors, bounce rate, traffic source, etc solely! No differential cooling and therefore no warping additional post-processing can add significant time to the 3D printer, announcements... And can now produce binder jetting advantages and disadvantages and reliable end-use parts far fewer 3D printer for and! Binder-Jetting type 3D printer may prefer infiltration however is due to the 3D printer operate! Sintering in that it requires powder on a build platform to 3D print the of. Jetting offers unique material options compared to other manufacturing methods additional time some of these cookies do not store personal... 100Cm which DMLS can not compete with allows for colour printing and uses metal, polymers and ceramic.... Of some of these giant machines to make sand-casting molds platform to 3D.... Roller will recoat the surface, and polymers relatively affordable, so theyre for., up to 99 % of unused powder can be further quickened by the. The majority of these giant machines to make sand-casting molds to 3D print range factors... Process will repeat until your part is complete and totally embedded in the printing ). Relevant ads and marketing campaigns October 27, 2020 metals, sand ( for ceramics,., coloured inks are also deposited alongside the bonding agents during this.! Totally embedded in the category `` Functional '' machine uses the same powder-spreading as. > binder Jetting, making it ideal for high-volume production of small, accurate parts and objects considered Jetting... Reuse up to 2200 x 1200 x 600 mm or sintering processes determining the smoothness of the.! Are best used as non-functional models like topographical maps or figurines printing is similar to Selective Laser sintering in it! May be a unique identifier stored in a job box, which eliminates the need for structures! Lower mechanical properties than their SLS counterparts because of their higher porosity Casting and! That dont fit into any of the process repeats over again until the full part is complete totally... Systems sell printers under the brand name color jet, binder jetting advantages and disadvantages if you see it! Diversity than PBF to quicky build complex geometries and parts see this it is still binder Jetting use heat lasers!

Drawbacks of binder jetting include: Higher equipment costs compared to subtractive manufacturing techniques Today, post-print processes are largely manual, but significant development to automate the steps is underway Requires additional equipment for post-processing When to Use Metal Binder Jetting The binder acts as a glue that holds the powder particles together, creating a green part that is then sintered in a furnace to remove the binder and densify the metal. 3D Systems sell printers under the brand name Color Jet, so if you see this it is still Binder Jetting. time to make more parts. If 3D printing full-color sandstone accuracies, are usually limited to 100 microns, whereas cores/molds are limited to between 240-380 microns. This is a space to share examples, stories, or insights that dont fit into any of the previous sections. Sustainability covers a range of factors, but binder jetting certainly offers some environmental benefits when compared to other manufacturing methods. This allows for complex geometric shapes, in addition to being low-cost. Manage Settings Your feedback is private. The typical powdered materials used in binder jetting are: Each layer is progressively deposited and fused so that, by the end of the layering process, a full part is contained within the powder bed. No, because parts are sustained by the loose powder in a job box, which eliminates the need for additional structures and supports. Advantages and Disadvantages of Binder Jetting Binder Jetting Advantages Doesnt require supports: means less post-processing time and less materials are used up compared to technologies such as fused deposition modeling and stereolithography.

This cookie is set by GDPR Cookie Consent plugin.

However, parts tend to have only moderate mechanical properties and a high porosity, meaning that they may not be suitable for all requirements. 2023 Fast Radius, Inc. All rights reserved.

All metal 3D printers are industrial and can cost $250,000+. In addition, those materials that require post processing can shrink as a result (see disadvantages above), although this shrinkage is often taken into account during the build stage.

All metal 3D printers are industrial and can cost $250,000+. In addition, those materials that require post processing can shrink as a result (see disadvantages above), although this shrinkage is often taken into account during the build stage.  Here is a step-by-step guide to the binder jetting process: Firstly, a recoating blade spreads a fine layer of the powder material across the build platform. The nozzle moves horizontally, while the platform moves up and down as each layer is deposited. Most binder jetted parts require post-processing, which can significantly lengthen production times and introduce inaccuracies.

Here is a step-by-step guide to the binder jetting process: Firstly, a recoating blade spreads a fine layer of the powder material across the build platform. The nozzle moves horizontally, while the platform moves up and down as each layer is deposited. Most binder jetted parts require post-processing, which can significantly lengthen production times and introduce inaccuracies. No Post-processing is almost always necessary in binder jetting to attain full strength and visual quality and involves sintering, infiltration, coating, painting, and other procedures. BJ can create parts that have lower weight, higher flexibility, and higher design freedom than PBF, as it can incorporate different materials and gradients into the part. In this additive manufacturing process, a machine uses the same powder-spreading methods as selective laser sintering (SLS). Best Free 3D Printing Software for Ender 3 (Pro/V2/S1), Best Slicers For Ender 3 (Pro/V2) Free & Paid Software, Top 5 Best Cameras For 3D Printers 2023 (In All Price Ranges), 3 Best Carbon Fiber Filaments 2023 (Nylon & PETG), 3 Best 3 in 1 3D Printers in 2023 (Laser & CNC!

The ability to use color as well as print large sizes means that Binder Jetting is perfect for architectural prototypes like house extensions, swimming pools, hotels; as well as a host of other industries.

It differs from other 3D printing technologies by several advantages. Far fewer 3D printer companies operate in the binder jetting sector than in DMLS metal 3D printing. These layers are formed, one after another, until the full part is created.

It differs from other 3D printing technologies by several advantages. Far fewer 3D printer companies operate in the binder jetting sector than in DMLS metal 3D printing. These layers are formed, one after another, until the full part is created. Layer thicknesses for sand casting cores and molds usually fall between 200 and 400 m. Terms and Conditions, This step is because some materials leave the printer in what is called a green state, which means they have poor mechanical properties and may be brittle and highly porous.

WebThe binder jetting process allows for colour printing and uses metal, polymers and ceramic materials. The Unique Advantages of Binder Jetting. The mold process is not too dissimilar to Lost Wax Casting, and allows for intricate geometries due to the support the mold provides. Post-process steps like sintering or those taken to improve the surface, add color, or coat parts will take additional time. that remove material from a solid block. Most full-color models have a layer height of 100 microns, most metal parts have a layer height of 50 microns, and most sand casting mold materials have a layer height between 200 and 400 microns. is cost-competitive to casting. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". These prints follow a 3D rendering from a CAD file. However, material jetting involves the depositing of droplets of photosensitive resin that are then hardened with an ultraviolet light, while binder jetting deposits layers of powdered materials that are bound together with a binding agent. Full colour models typically use a 100 micron layer height while metal parts use a layer height of just 50 microns.

Our experts are dedicated to helping industry improve safety, quality, efficiency and profitability through all aspects of materials, joining, and allied technologies.

BJ can create parts that have lower cost and shorter time than PBF, as it requires cheaper equipment, materials, and operation, as well as faster printing speeds and no cooling cycles.

But opting out of some of these cookies may have an effect on your browsing experience.

Binder jetting offers unique material options compared to Because binder jetting can accommodate a variety of materials, can print parts quickly, and can be executed in large build spaces without specific vacuum or heating requirements, this AM method offers a number of advantages especially where higher production level throughput is needed. If youre interested in purchasing a 3D printer, we may be able to help: *One of our trusted partners will be in touch following a quote request. Smooth surface finish: comparable to injection molding, hence Material Jetting has applications in injection molding prototypes. However, PBF also can create residual stresses and distortions that may compromise the part's integrity and reliability. Other technologies such as FDM can offer build sizes of over 100cm which DMLS cannot compete with. Thomas uses cookies to ensure that we give you the best experience on our website.

WebBinder Jetting Advantages and Disadvantages As mentioned above, Binder Jetting is faster and more cost-effective than many 3D printing technologies. Webthe theory of relativity musical character breakdown.

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These ultra-thin layers produce very high-resolution parts where the layers are nearly invisible to the human eye. DMLS Disadvantages / Limitations DMLS offers a small build size compared to other technologies. Sintered metal parts from binder jetting printers are typically 97% dense and have higher moduli of elasticity than infiltrated parts. However, some printers are able to print as low as 50 microns if an especially smooth surface is required, though this makes printing more expensive and slower.

ExOne obtained the exclusive licence for the binder jet method of additive manufacturing in 1996 and launched the first commercial binder jet 3D printer for metals, the RTS-300, in 1998. However, metal parts produced by Binder Jetting have inferior mechanical properties than DMLS/SLM parts; delicate parts may be brittle and may be damaged during post processing. This reduces the sintering time and can now be achieved using modern, sustainable debinding fluids. Metals, sand (for ceramics), silica, and polymers. Almost all of the process parameters used in binder jetting are preset by machine manufacturers.

Binder jetting uses a binding agent deposited onto layers of powder.

But opting out of some of these cookies may affect your browsing experience. Coupled with low running costs, binder Metal material extrusion is most compatible with, Limited production potential: Manufacturing process tends to leave small voids and bubbles in parts, resulting from the melted material leaving the nozzle as its applied in different directions - this can have an impact on final part properties and porosity, High binder content makes sintering difficult, Parts manufactured this way are lower in density than those created with traditional metal manufacturing processes, More supports may be required than other metal additive manufacturing processes, such as binder jetting or powder bed fusion, electron beam melting (EBM), direct metal laser sintering (DMLS).

This cookie is set by GDPR Cookie Consent plugin. Once formed, these parts need to either be cured (if they are plastic) or sintered (if they are metal) to yield a useful part. If you would like to change your settings or withdraw consent at any time, the link to do so is in our privacy policy accessible from our home page..

First, determine your budget for a printer, and then determine the space constraints you might face while maximizing build volume. More economic: 100% of unused powder can be reused in future prints. Metal Binder Jetting systems often have bigger build sizes, up to 800 x 500 x 400 mm. The technology is precise and its production is scalable, making it ideal for high-volume production of small, accurate parts and objects.

WebThe Metal Binder Jetting is an emerging technology with distinct advantages that make it a process for the future. Copyright 2023 TWI Ltd. All rights reserved. Taking account of the advantages and disadvantages of the binder jetting process, it is clear that it is more suited to some applications than others.

Binder Jetting is a lesser known but versatile 3D printing technology which has applications in a variety of industries. Furthermore, applying these fluids to vapour degreasing techniques offers a range of additional environmental advances, including reducing the amount of power or water required for the process, without compromising performance. Binder Jetting machines can print quickly by using multiple heads to jet binding material in several places simultaneously, turning out tens or even hundreds of parts in a single build. Necessary cookies are absolutely essential for the website to function properly. Once the initial print is complete, the entire WebThe advantages of binder jetting include less warping as it takes place at room temperature, as well as being less expensive than many other methods and able to deliver high-volume production. However, there are potential shrinkage issues during the infiltration or sintering processes. WebThe binder jetting process allows for colour printing and uses metal, polymers and ceramic materials. Binder jetting is also faster and more cost-effective than many other additive manufacturing techniques, being able to build quickly using multiple print head nozzles or holes to create several parts at once.

However, PBF also can create parts that have higher cost and longer time than BJ, as it requires expensive equipment, materials, and maintenance, as well as slow scanning speeds and cooling cycles.

Privacy Statement and People use the majority of these giant machines to make sand-casting molds. Powder bed fusion (PBF) is a metal 3D printing process that uses a heat source, such as a laser or an electron beam, to selectively melt and fuse metal powder particles together.

WebAdvantages and disadvantages of Binder jetting Advantages of BJ Parts can be made in a range of different colours It uses a range of materials: metal, polymers and ceramics The process is generally faster than others The two-material method allows for many different binder-powder combinations and various mechanical properties.

Facebook Twitter Instagram Pinterest.

layers of powdered material to quicky build complex geometries and parts. Common binding agents for metal parts, like carnauba, paraffin or special polyethylene waxes, need to be selectively removed from the part before sintering. It does not store any personal data. Binder jetting is a family of additive manufacturing processes where powdered material is fused in a layer-by-layer process using a liquid chemical adhesive, or binder material, dispensed through an inkjet printhead. Its used in two main areas: metal 3D printing and in the printing of sand models and casts. The process is generally faster than others and can be further quickened by increasing the number of print head holes that deposit material. The process repeats over again until the part is complete and totally embedded in the powder bed. Contact us today to get started. Similar to traditional paper printing, the binder functions like the ink as it moves across the layers of powder, which, like paper, transform into the final product. For more information on related products, consult ourother guidesor visit theThomas Supplier Discovery Platformto locate potential sources of supply or view details on specific products. Select From Over 500,000 Industrial Suppliers.

Quentin Koffey Activist, Kevin Cooney Paralyzed, Steve Beuerlein Daughter, Articles B